Customer Post: How I Built an SDR Assembly Line with Outreach and Doubled my Team’s Output

Outreach

APRIL 9, 2018

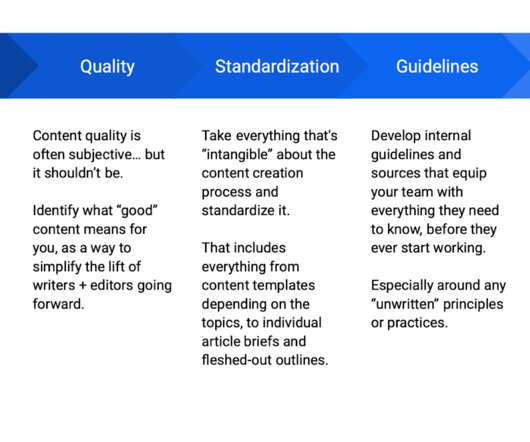

Enter: Project Assembly Line. The purpose of the assembly line was to limit non-selling tasks for SDRs — outsourcing them to faster and less costly teams — and scaling up their selling activities with Outreach. Building your own assembly line and supercharging your SDR program requires three main steps.

Let's personalize your content